Dosing and volumetric measurement including weighing of light-weight materials (e.g. perlite)

- Screw conveyor

- Butterfly discharge valve

- Container with volumetric measurement system and additional balance

- Linear transducer for set point setting

- Tuning fork for deactivation

- Working volume 500 l

- Butterfly discharge valve

- 2-way distribution

- Downpipe to mixer 1 and mixer 2

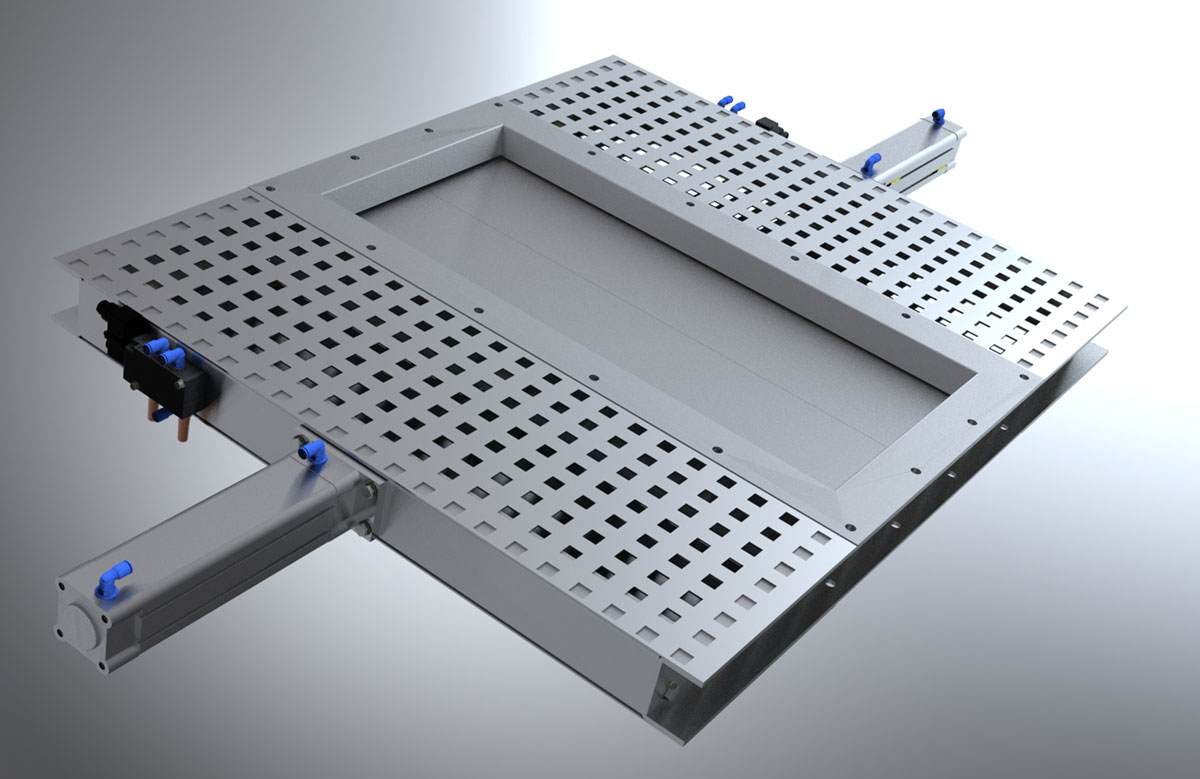

Flat slide valve and silo emergency gates

The product range of flat slide valves ranges from manual emergency slide valves to pneumatically or electrically operated dosing slide valves. In detail, they have the following features:

- The slider plate can be sealed by an adjustable stuffing box

- The lateral sealing of the slider plate is ensured by felt or Vulkolan strips

- Deflector frames, which hold back the material pressure from the sealing strips can be used

- The slider plate position is monitored via inductive limit switches

- The structure of all flat slide valves is designed for a long service life

- The size of the flat slide valves can be specifically customised

We can also supply all flat slide valves in stainless steel or aluminium.

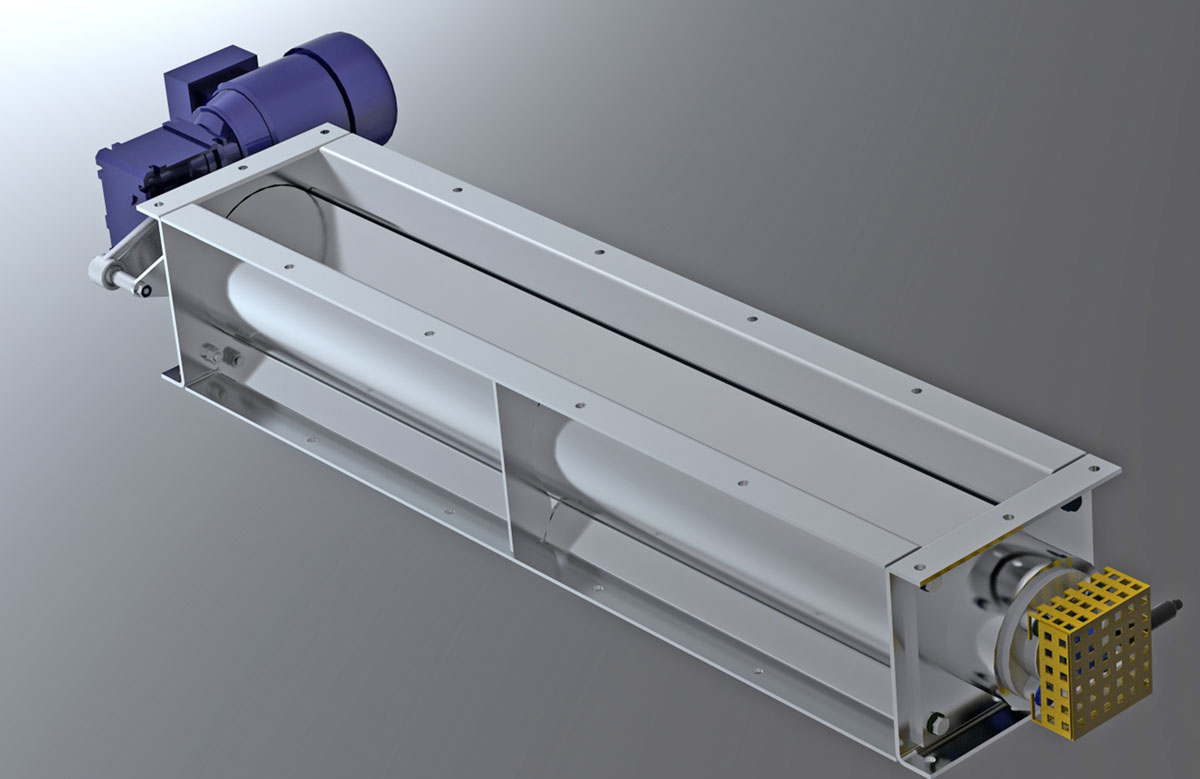

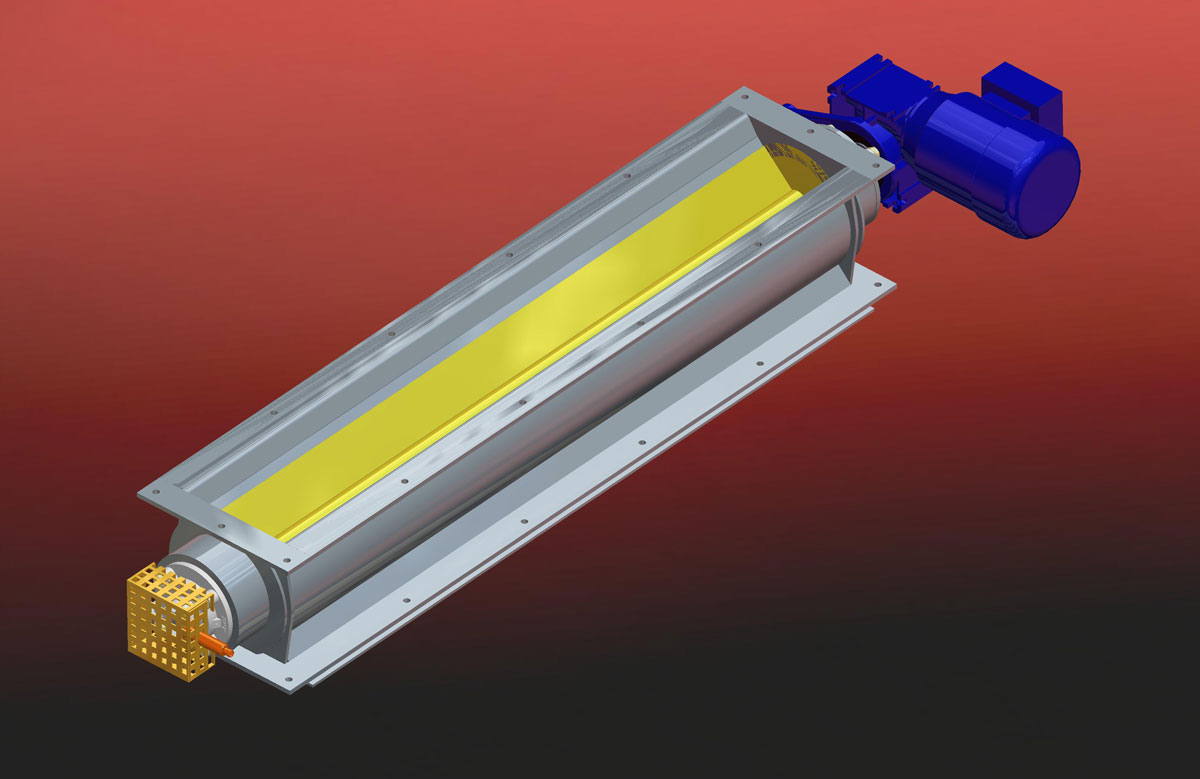

Box feeder

- Heinrich Welb & Söhne manufactures the box feeders in an extremely robust design. This is because these conveyor elements are mostly subjected to very high material stress.

- All baffles are lined with wear protection material such as Hardox, PE1000 or rubber.

- The use of a large drum diameter ensures consistent power transmission.

- The belt supplied is a rubber belt or steel cable belt, depending on the use.

- Shredders can also be used for discharge aids.

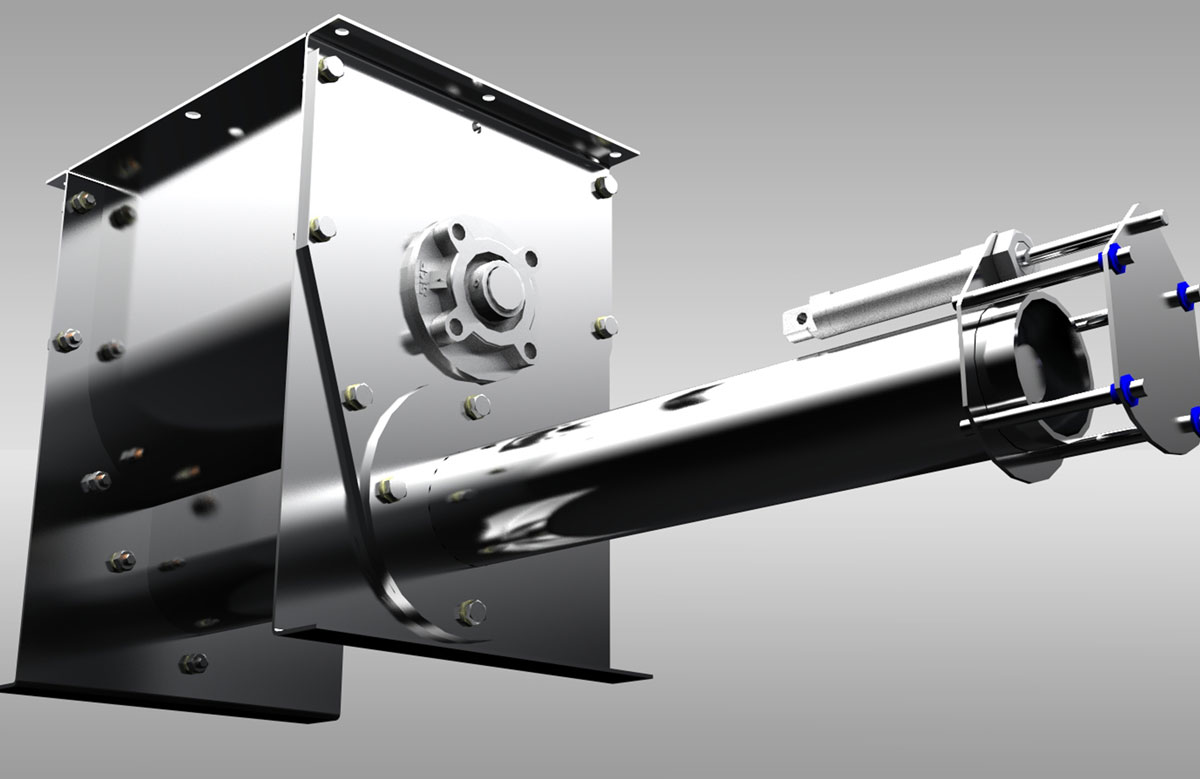

Small component dosing device

- The small component dosing device of Heinrich Welb & Söhne is based on a screw conveyor with a superordinate material loosening system designed according to the discharge behaviour of the material conveyed.

- This system guarantees a high dosing accuracy as well as a continuous and undisturbed operation of small component plants.

- The dosing performance is variable by the use of frequency converters.

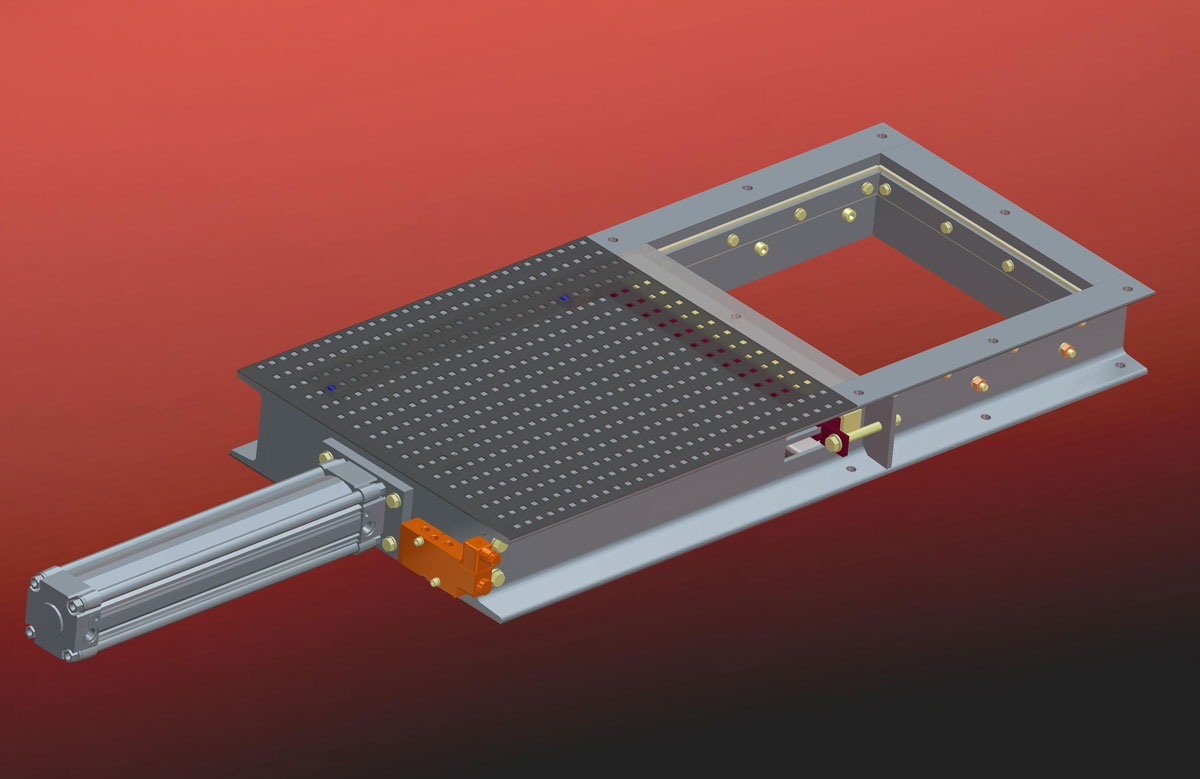

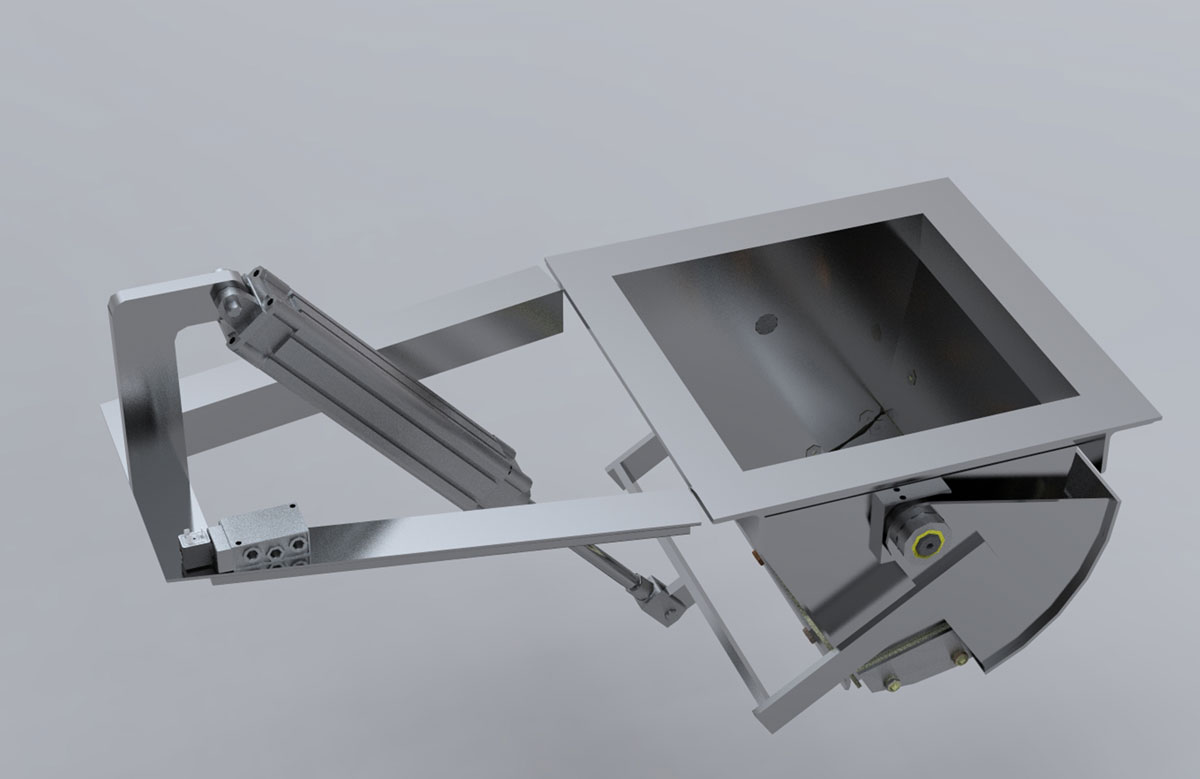

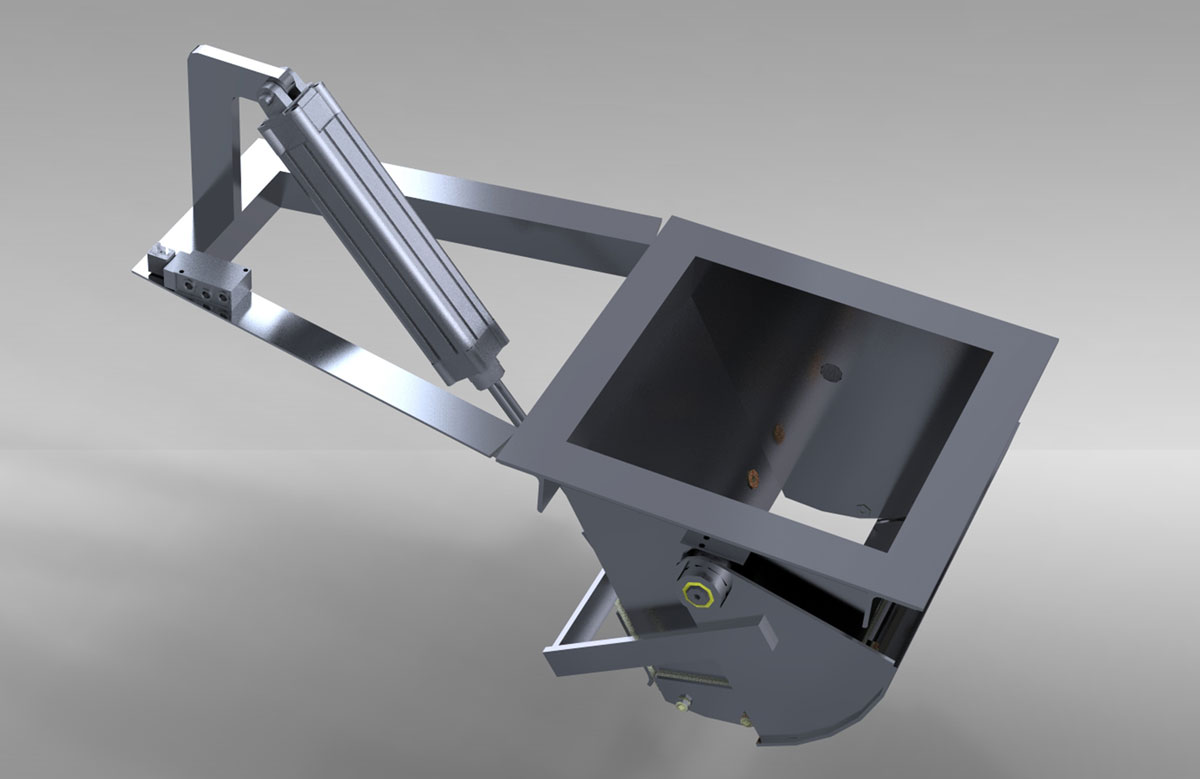

Segment slider valve

- The electro-pneumatic actuation of segment slider valves of Heinrich Welb & Söhne act as gates under silo discharge for sands and granular bulk materials. Another area of use is the dosing from silos into balances.

- There are multiple options for regulating the outlet cross-section in order to maintain as accurate a dosing of bulk solids as possible:

- mechanically using a slider plate

- electro-pneumatically by only partial extension of the cylinder

- by oscillating flap actuation using the pneumatic cylinder

- Heinrich Welb & Söhne manufactures all segment slider valves as stable and durable welded structures.

- We also manufacture the segment slider valve in stainless steel if you request for it.

- The processing quality is of a high level due to an intensive monitoring in production

We would be glad to send you detailed information about our segment slider valves.

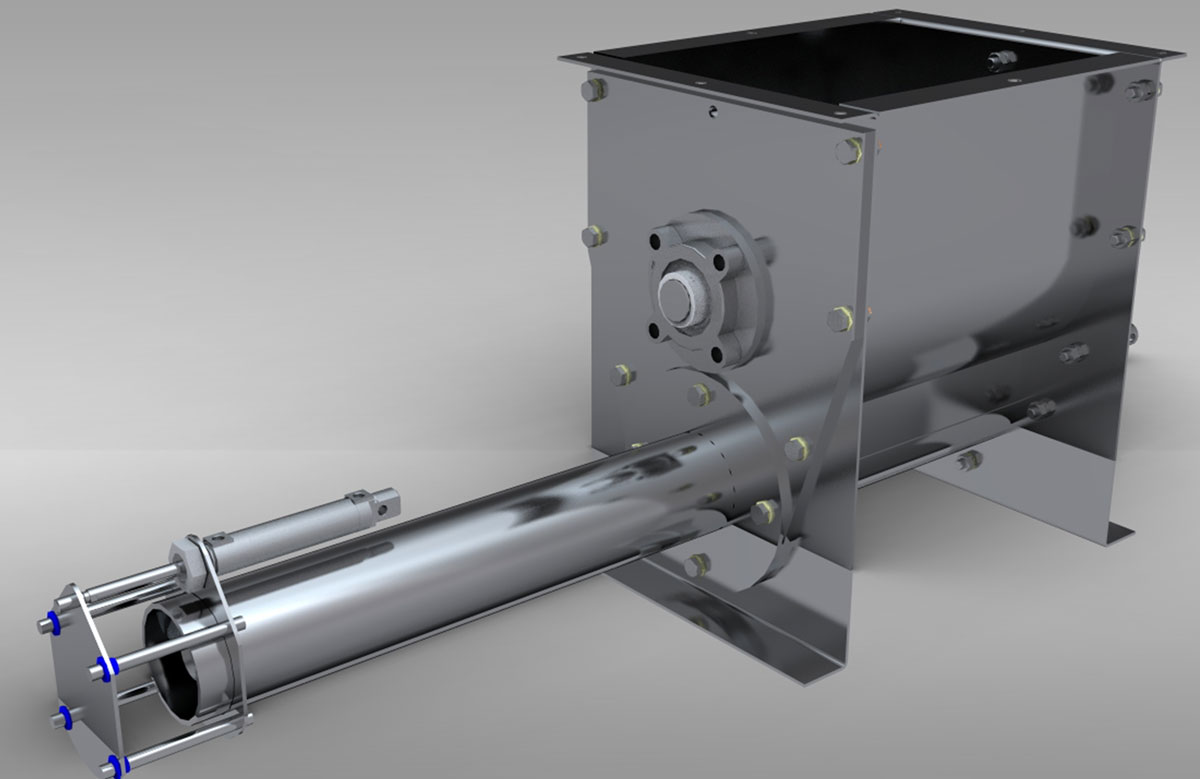

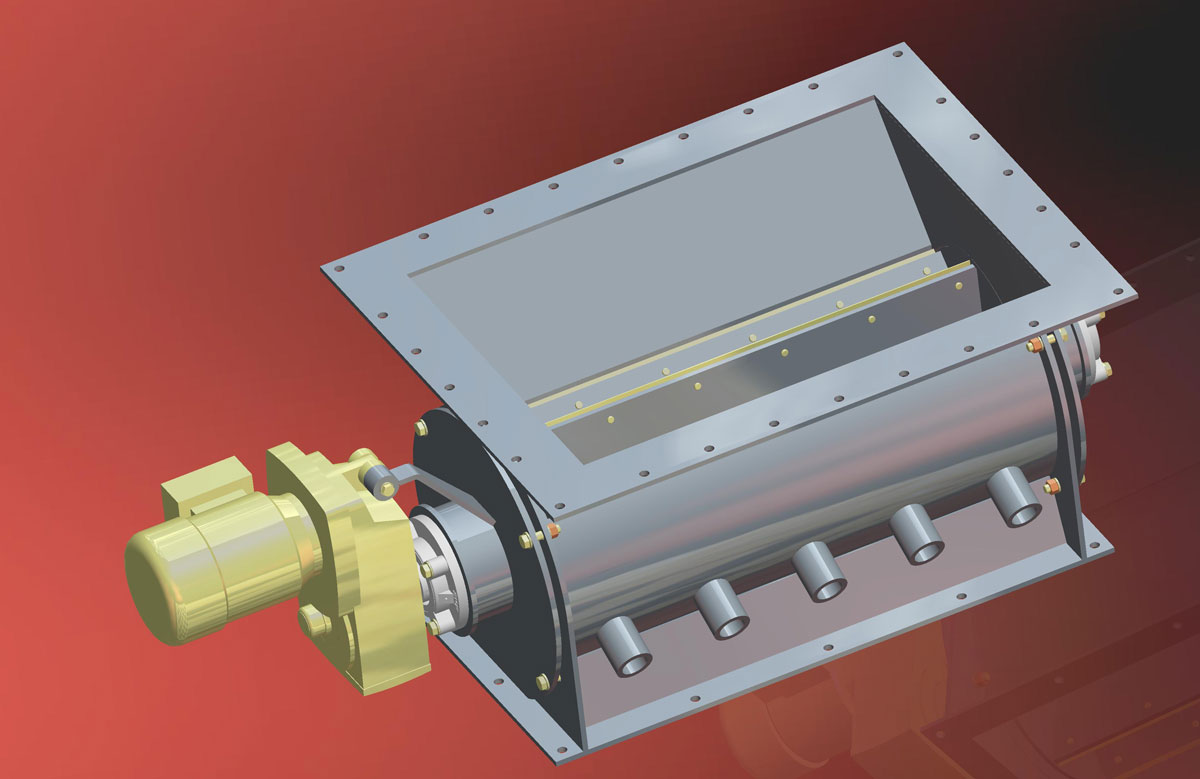

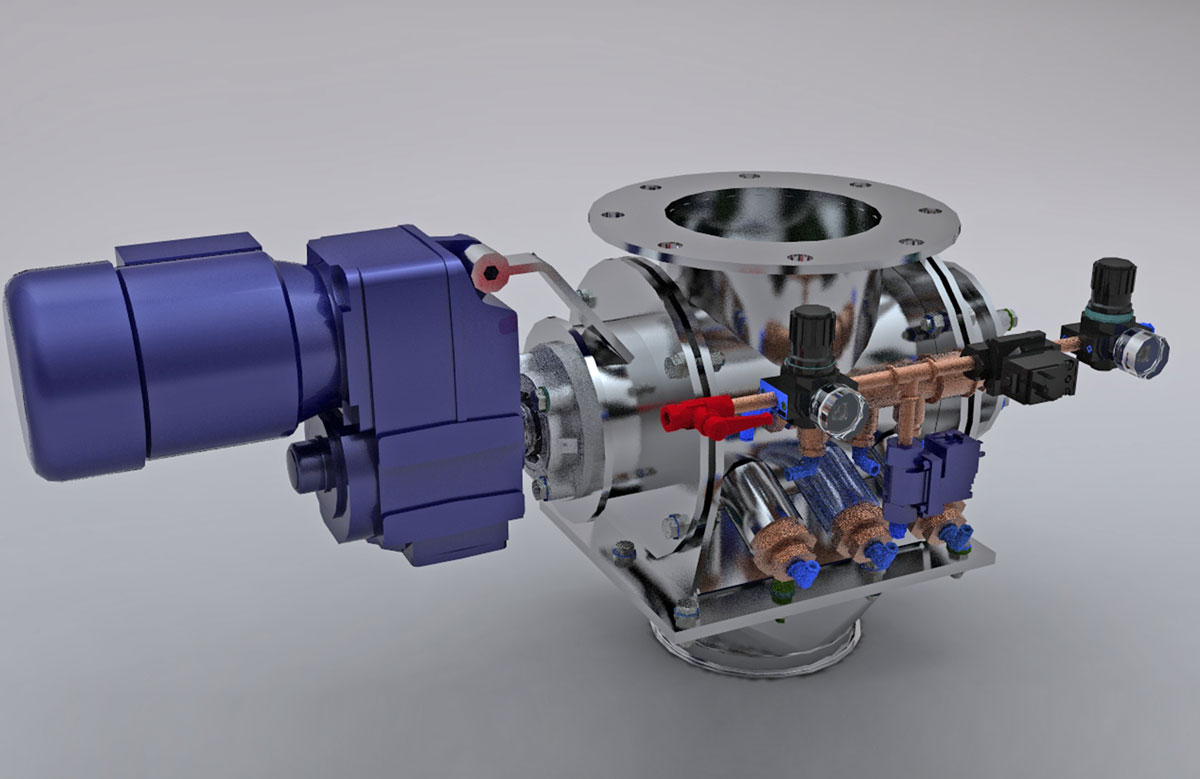

ZD type rotary gate valves

- The rotary gate valves of Heinrich Welb & Söhne cover a capacity range of 1 m³/h to 150 m³/h.

- They are made from a stable, welded steel structure.

- Sealing of shaft outlet is enhanced due to the use of lateral platform panels and the use of stuffing boxes and protective bushings on both the sides.

- The rotor can be sealed towards the stator with felt or Vulkolan strips.

- Round inlets / outlets are provided for if needed.

- The rotary gate valves of Heinrich Welb & Söhne are customised for the individual mounting conditions of the plants.

- The use of frequency converters makes the capacity range of the rotary gate valve fully variable.

- The individual chambers can be emptied using a purging air cleaning system if needed.

- We can also manufacture all the rotary gate valves in stainless steel.

We would be glad to send you detailed information about our ZD type rotary gate valves.