GBW type bucket conveyors

- The GBW type bucket conveyors of Heinrich Welb & Söhne cover a capacity range of 5 m³/h to 180 m³/h.

- The bucket conveyor base is made of a strong sheet and profile steel structure.

- The tension drum is equipped with opposing screw blades.

- The bucket conveyor ducts have an installation or maintenance opening at a

- readily accessible height.

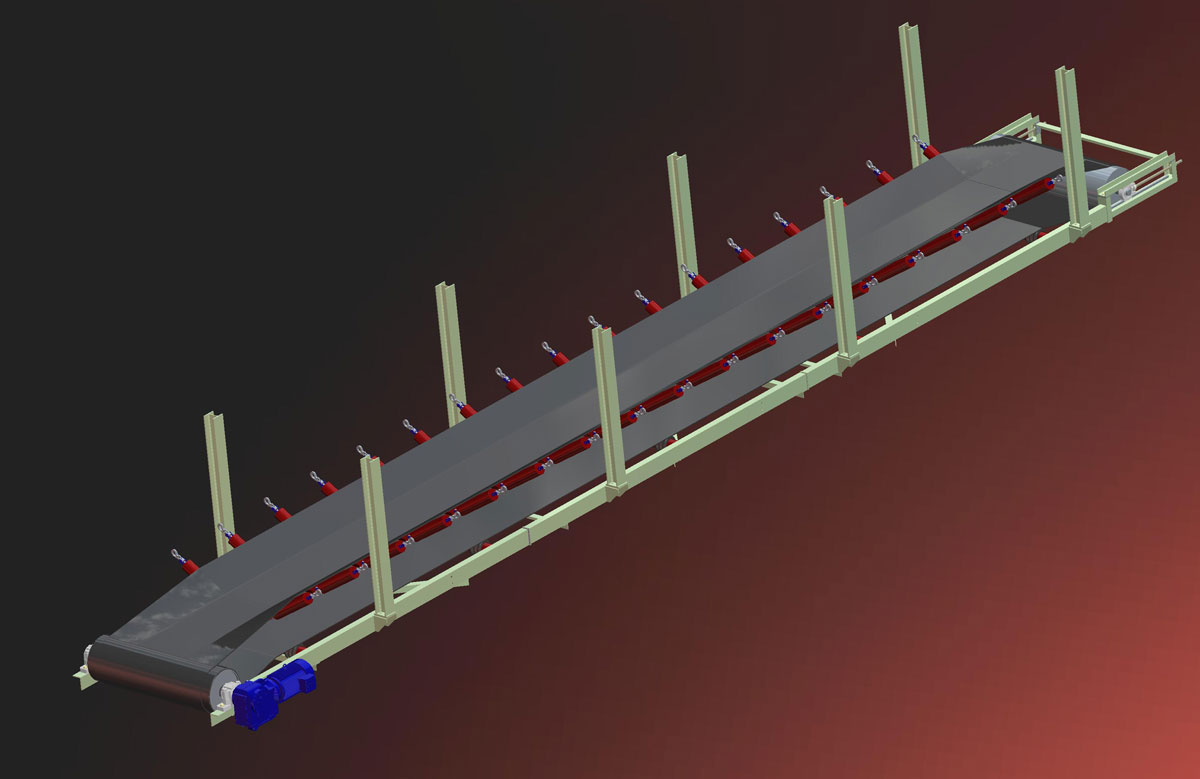

Conveyor belts and Flexowell conveyors

Heinrich Welb & Söhne can also look back on years of experience in the construction of conveyor belts and Flexowell conveyors.

The palettes of the belts cover all the conveying capacities and we supply them in structural variants such as open variant, dust-tight variant or as slider belt. All structures have been carefully made and are extremely stable.

The palettes of the belts cover all the conveying capacities and we supply them in structural variants such as open variant, dust-tight variant or as slider belt. All structures have been carefully made and are extremely stable.

Flexowell conveyors

Heinrich Welb & Söhne can also look back on years of experience in the construction of conveyor belts and Flexowell conveyors.

The palettes of the belts covers all the conveying capacities and we supply them in structural variants such as open or dust-tight variant or as slider belt. All structures have been carefully made and are extremely stable.

The palettes of the belts covers all the conveying capacities and we supply them in structural variants such as open or dust-tight variant or as slider belt. All structures have been carefully made and are extremely stable.

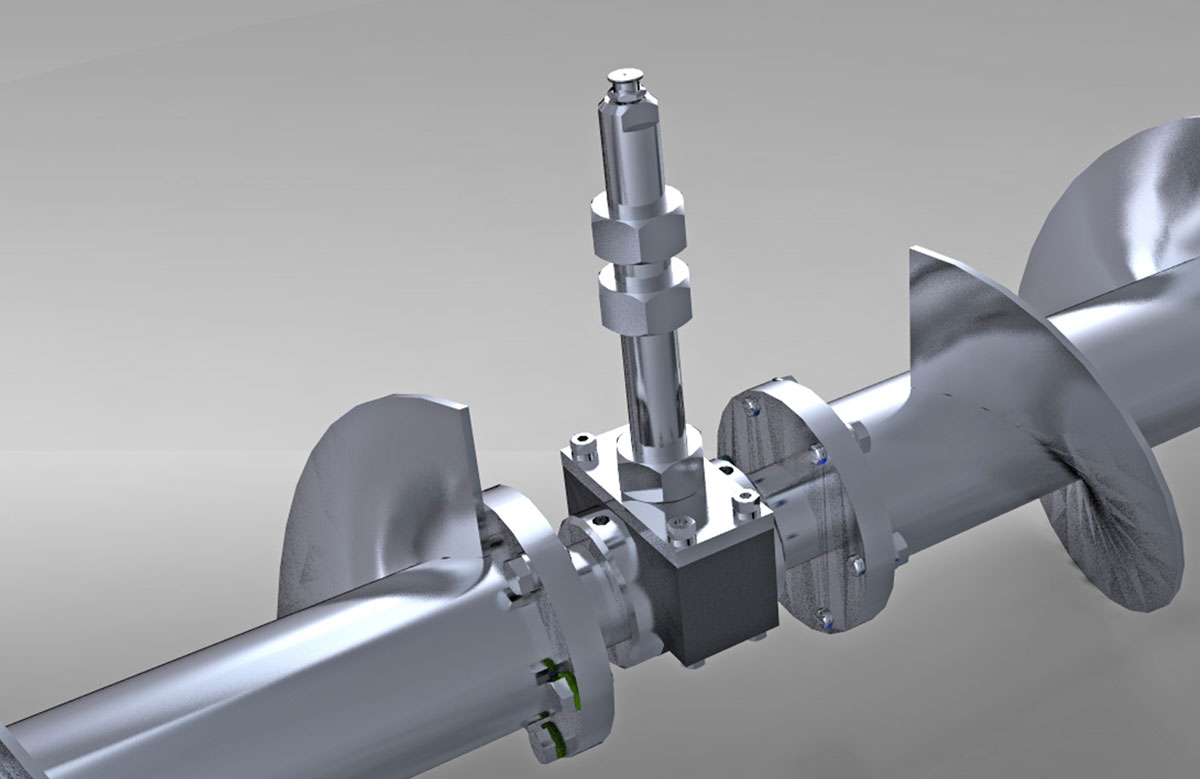

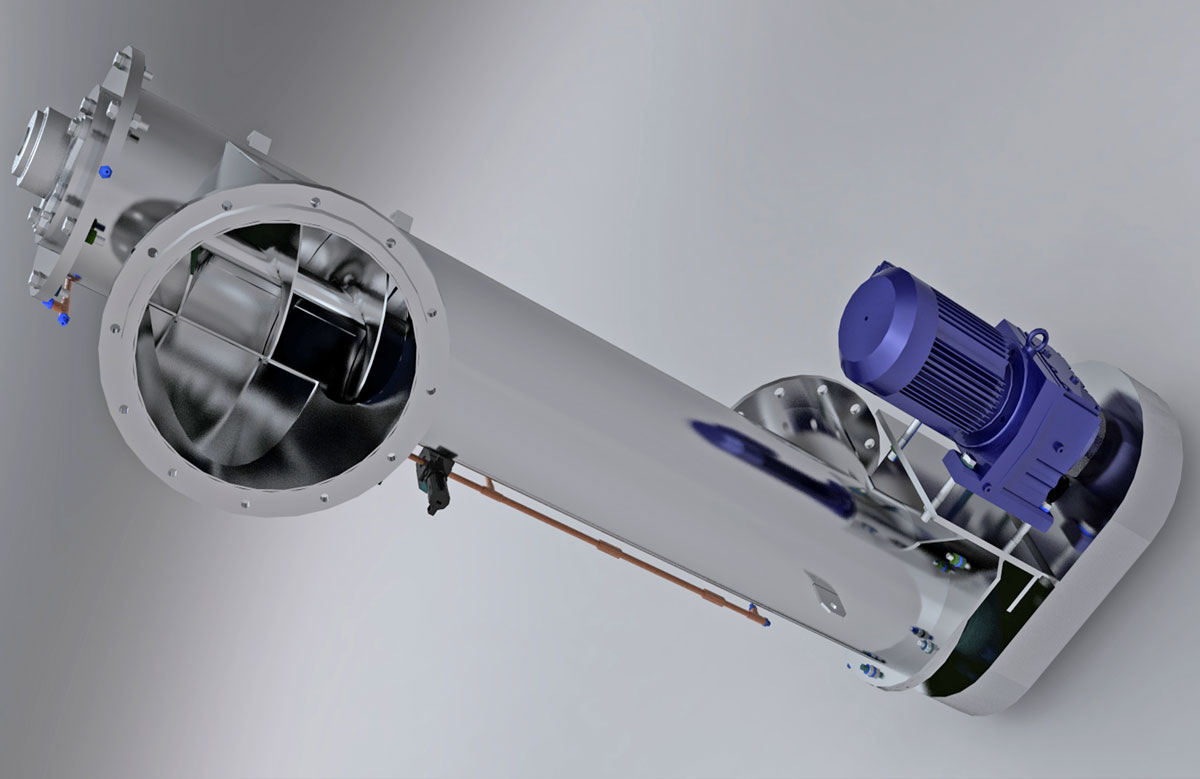

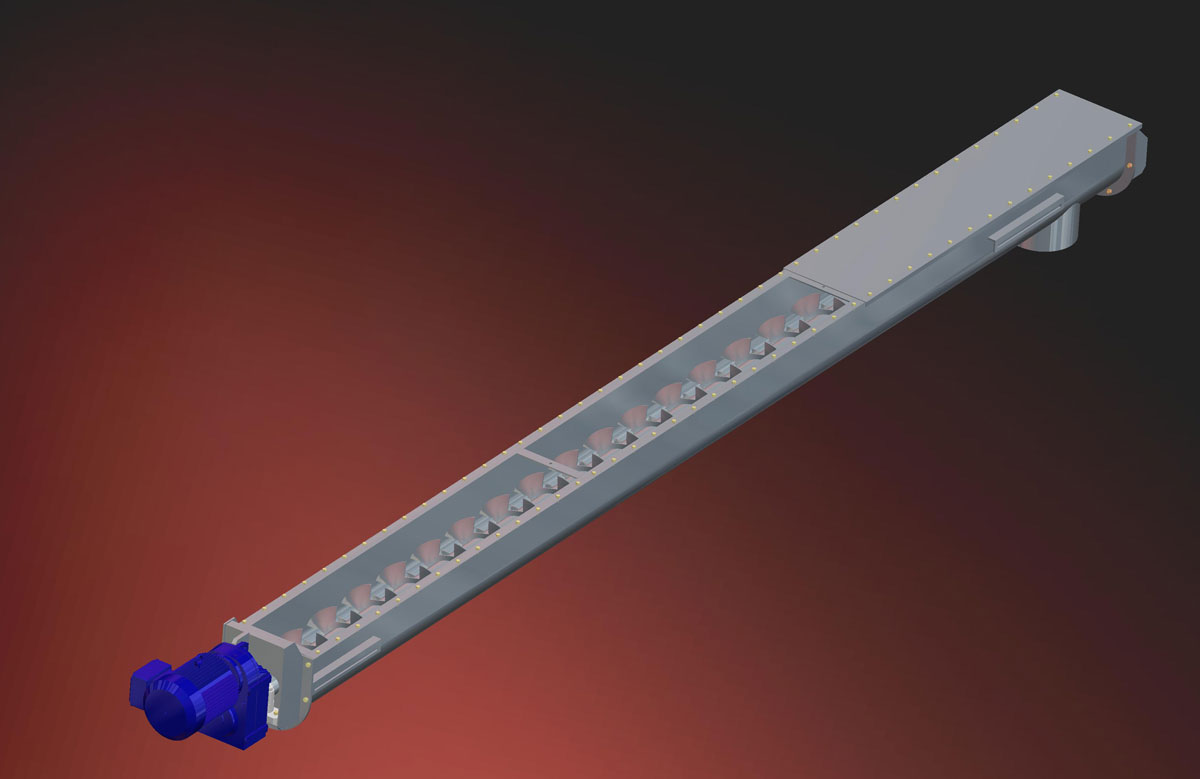

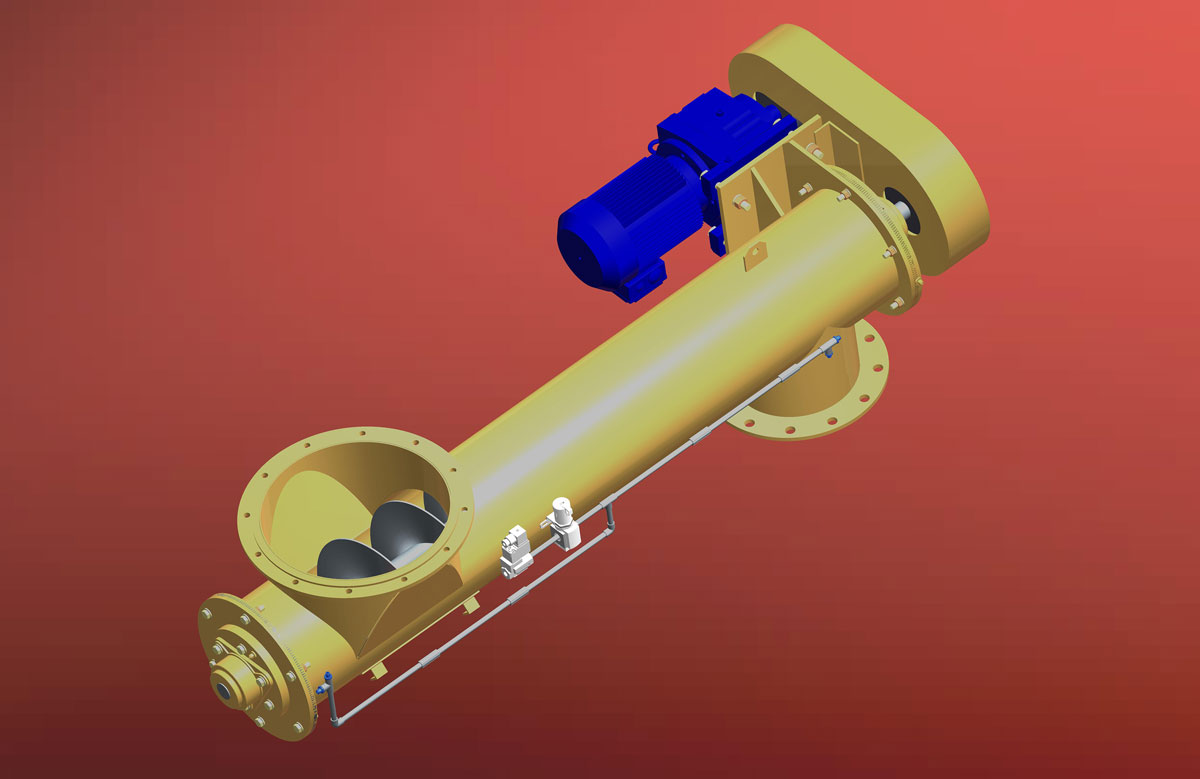

Pipe or trough screw conveyors

Heinrich Welb & Söhne makes screw conveyors as pipe screw conveyors or trough screw conveyors depending on the technical requirement.

They are specially customised upon our customers’ request and their design is extremely protective of the material and low on wear.

The conveying capacities are in the range of smallest dosing of 0.5 m³/h and extend up to 200 m³/h in large plants. The pipe and trough screw conveyors of Heinrich Welb & Söhne, which can naturally be produced in stainless steel as well, specifically stand out due to the following points:

They are specially customised upon our customers’ request and their design is extremely protective of the material and low on wear.

The conveying capacities are in the range of smallest dosing of 0.5 m³/h and extend up to 200 m³/h in large plants. The pipe and trough screw conveyors of Heinrich Welb & Söhne, which can naturally be produced in stainless steel as well, specifically stand out due to the following points:

- stable welded structure

- adjustable stuffing boxes / felt ring hubs, each with protective bushings

- tests are conducted in a pilot plant for goods that are difficult to transport

- for abrasive materials conveyed, the worm shaft is coated or the screw blade is made of high quality materials (e.g. Hardox 500)